Product Code : 06

Brand Name : BRILLIANT PROCESS

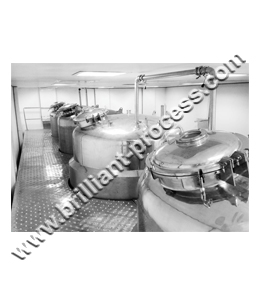

Capacity : 1,000 Ltr to 30,000 Ltr

The plant is designed to be operated by one operator and one helper, saving on precious man-power cost. Sugar syrup and manufacturing vessels are provided with Jacket for heating and cooling, designed for internal vacuum to facilitate transfer of sugar directly from stores to sugar syrup vessel.

Salient Features:

Sugar syrup is transferred to manufacturing vessel through online sugar syrup pre-filter by vacuum.

Entry of all propeller agitators are from bottom through a specially designed cartridge mechanical seal with TC / TC seal face.

The advantage of the bottom propeller agitator over the conventional agitator is that there are no vibrations of shaft, no couplings in the drive assembly, leading to lower maintenance cost.

Pipes, pipe fittings and valves are of SS 316, seamless, internally electropolish with TC unions and silicon Gaskets.

Manhole of all the vessels are equipped with davit fitting and the cover of the manhole slides instead of being lifted.

Values like current product temperature are displayed digitally on the electrical control panel.

The mechanical seal is equipped with a water circulating system and has a water detection sensor which trips the motor, ifthe water circulation to the seal is interrupted.

Load Cell & PLC System also provided on Client Request.

Quick Enquiry Form: