Product Code : 31

Brand Name : BRILLIANT PROCESS

Capacity : 5 Liter to 10000 Liter working Capacity

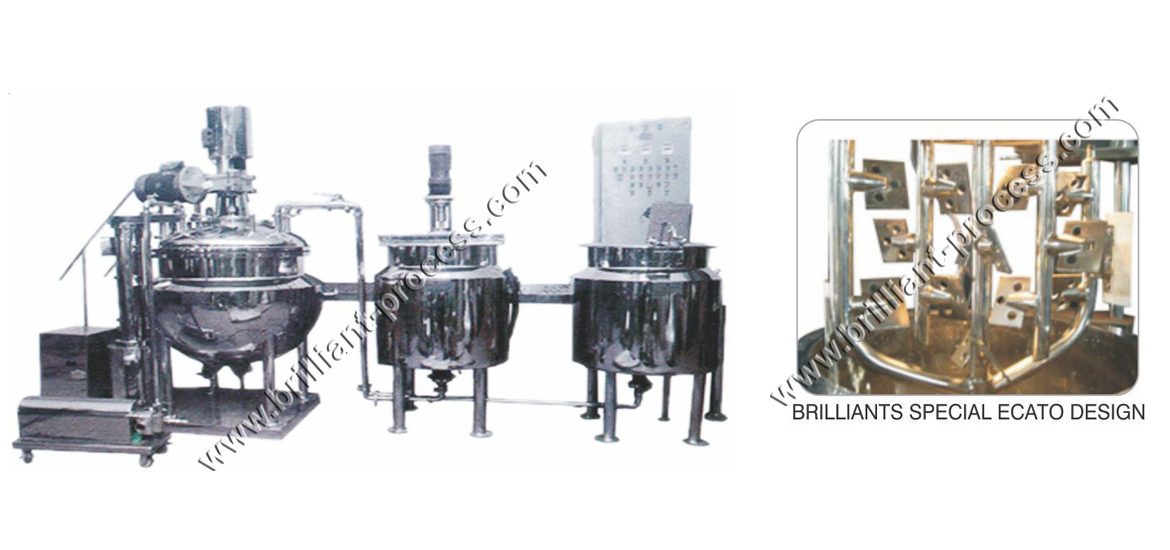

Brilliant’s Ointment ‘Multi-Mix’ manufacturing Plants are ideal tools for the pharmaceutical & cosmetic industries for the production of Ointment, Cream, Lotion, Gel, Tooth Paste & emulsions & homogenization.

Fully automatic Ointment, Cream, Tooth Paste, Gel manufacturing plant consisting of

- Pre determined water phase vessel

- Pre determined oil, wax, petroleum jelly phase vessel

- Vacuum Homogenizer Mixer vessel

- Vacuum Pump

- Storage vessel

- Interconnecting pipeline

- Transfer Pumps (Bump Pump, Lobe Pump & Metering pumps)

- Integrated automatic control panel

- Working Platform

Design Features :

Design compliance with cGMP

- Integrated Cleaning in Place-CIP

- Sterilizing In Place-SIP as an Option

Materials

- Product Contact AISI 316L

- Food Grade silicon rubber for seal

Water Phase Vessel

- Jacket for heating & cooling

- Heating Jacket Pressure (4 bar)

- Heating by steam or hot water circulation

- Propeller stirring with top mounting

Water Phase Vessel

- Jacket for heating & cooling

- Heating Jacket Pressure (4 bar)

- Heating by steam or hot water circulation

- Propeller stirring with top mounting

- Temperature controller & safety pressure Valve

- Bottom discharge with valve

Wax Phase Vessel

- Jacket for heating & cooling

- Heating Jacket Pressure (4 bar)

- Heating by steam or hot water circulation

- Propeller stirring with top mounting

- Temperature controller & safety pressure Valve

- Bottom discharge with valve

Manufacturing Vacuumize Homogenizer Vessel

- Jacket for heating & cooling

- Vacuumize process

- Vessel Inside Pressure (-1 /+2 Bar)

- Heating Jacket Pressure (-1 /+6 bar)

- Heating by steam or hot water circulation

- Agitator mixer with self pressure Teflon scrapper

- Scrapper cleanly working on both side

- High speed Homogenizer with toothed Rotor – stator type

- RPM sleeplessly with variable speed drive for agitator & Homogenizer

- High shear & pressurization of the homogenizer

- Thus homogenization of high viscosities up to 400.000 mPas

- Homogenizer mounted on lower position in the centre of vessel

- Top lid with motorized top lid for lifting & lowering

- Safety Interlock process with limit switch

- Connection for Vacuum, Charging, Eye glass window, Light glass, CIP,SIP, Pressure gauge & safety valve

- Temperature controller & safety pressure Valve

- Bottom discharge with valve

Vacuum System

- Water Ring Vacuum Pump

- Vacuum gauge & Vacuum relief valve

Storage Vessel

- Skid type storage vessel

- Bottom cone is Jacket for heating

Inter Connecting Pipe

- Inter connecting Pipe line of all vessel for transfer Water, Wax & products

- Recirculation in manufacturing vessels

- Vacuum connecting pipe

Working Platform

- Rigid structure with anti slipping embossed plat

- Made from AISI 304

Controls & Visualization

- Electric Controls with digital display

- Optional PLC Controls with HMI Touch screen

- RPM and Process time entries

- Temperature controls- Heat / cool

- Vacuum start- Stop

- Integrated Data Recording for batch

Safety Features

- Emergency stop button

- Safety vacuum relief valve & Indicator Gauge

- Safety Pressure Valve

- Limit switch at top lid

Quick Enquiry Form:

| OINTMENT / CREAM PLANT TABLE | |||||||

| BATCH (KG) | WAX PHASE VESSEL (CAPACITY) Ltrs. | WATER PHASE VESSEL (CAPACITY) Ltrs. | MANUFAC- TURING VESSEL (CAPACITY) Ltrs. | STORAGE VESSEL (CAPACIY) Ltrs. | APPROX LENGTH (B) MM | APPROX WIDTH (B) MM | APPROX LIFTED HEIGHT (H) MM |

| 50 | 35 | 35 | 70 | 78 | 3500 | 1200 | 2135 |

| 100 | 70 | 70 | 140 | 156 | 4110 | 1300 | 2200 |

| 200 | 140 | 140 | 280 | 312 | 4580 | 1400 | 2600 |

| 250 | 175 | 175 | 348 | 388 | 5050 | 1550 | 2755 |

| 300 | 210 | 210 | 420 | 468 | 5050 | 1550 | 2850 |

| 500 | 350 | 350 | 700 | 780 | 5550 | 1750 | 3200 |

| 1000 | 700 | 700 | 1400 | 1560 | 6070 | 2000 | 3600 |